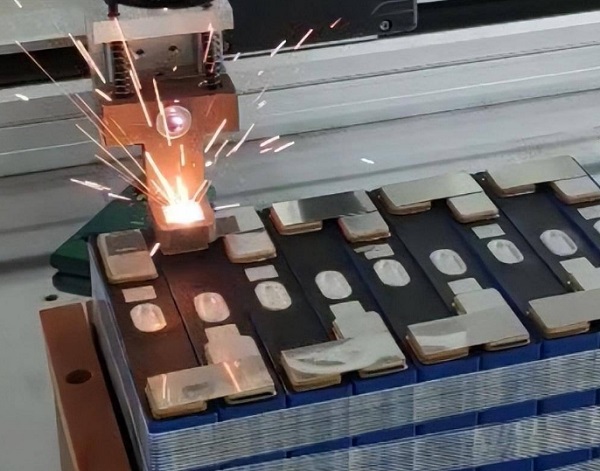

Laser transmission efficiency of lithium battery laser welding machine

In the production of lithium batteries, laser welding machines play a key role, and the efficiency of laser transmission directly affects the welding quality and production efficiency. What is the laser transmission efficiency of the lithium battery laser welding machine? Haiwei Laser will give you a professional introduction.

Key components that affect transmission efficiency

Laser generator: The laser generator is the source of laser generation, and its performance has a significant impact on transmission efficiency. A high-quality laser generator can output stable and high-energy laser beams. For example, some advanced fiber laser generators use special gain media and pump technology, which can effectively improve the efficiency of laser generation and lay the foundation for efficient laser transmission. If the performance of the laser generator is poor and the generated laser energy is unstable, the transmission efficiency will naturally be difficult to guarantee.

Transmission fiber: Transmission fiber is responsible for transmitting laser from the generator to the welding head. The quality, length, and degree of bending of optical fibers are all crucial. Low loss optical fibers can minimize the energy loss of lasers during transmission. Generally speaking, the shorter and less bent the optical fiber, the higher the transmission efficiency. In some compact laser welding machines, by reasonable layout, shortening the fiber length, and reducing unnecessary bending, the laser transmission efficiency can be significantly improved. Moreover, the application of special optical fibers, such as large mode area fibers, can better transmit high-power lasers and further improve transmission efficiency.

Optical lens assembly: The optical lens assembly in the welding head is used to focus and adjust the laser beam. The material, coating, and cleanliness of the lenses can affect laser transmission. High quality lenses with stable optical performance can accurately focus and guide lasers. For example, lenses using anti reflective film technology can effectively reduce the reflection loss of laser on the surface of the lens and improve transmission efficiency. But if the lens is stained or worn, the laser will scatter, absorb, etc. when passing through, resulting in a significant decrease in transmission efficiency.

Performance of transmission efficiency in practical applications

In the practical application of lithium battery production, the laser transmission efficiency can usually reach 70% -90%. For simple welding tasks, such as spot welding of extreme ears, with the equipment components in good condition, the transmission efficiency can approach 90%, enabling efficient completion of welding work. However, when faced with complex welding processes such as continuous welding of multiple layers of materials, due to the need for laser to penetrate different materials, there may be a certain loss of energy, and the transmission efficiency may drop to 70% -80%. However, by continuously optimizing equipment components and process parameters, high transmission efficiency can still be maintained to meet the high-precision requirements of lithium battery production.

The laser transmission efficiency of lithium battery laser welding machine is affected by multiple key components. In practical applications, although there may be fluctuations in the complexity of welding tasks, selecting high-quality components, designing optical paths reasonably, and regularly maintaining equipment can effectively improve and maintain high laser transmission efficiency, providing strong guarantees for high-quality welding of lithium batteries.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY