What are the safety hazards of lithium battery pack production lines and how can they be prevented?

Whether it is a lithium battery pack production line or other laser equipment, safety issues are crucial. Even a slight mistake can lead to serious accidents due to safety hazards, not only endangering the lives of personnel, but also causing huge losses to the enterprise. Next, based on practical work experience, we will provide a detailed explanation of the safety hazards and effective preventive measures that exist in the production line.

Electrical safety hazards and prevention

Leakage risk

Lithium battery production equipment is mostly electrical equipment, and long-term operation, line aging, equipment failure, etc. may all lead to leakage. Once workers come into contact with the leaking parts, electric shock accidents may occur. During prevention, regular inspections of electrical circuits and equipment should be carried out, and aging or damaged circuits should be replaced in a timely manner. Install reliable leakage protection devices to ensure that the power can be quickly cut off in case of leakage.

Overvoltage and overcurrent

During the production process, the starting and stopping of equipment may generate instantaneous overvoltage and overcurrent, which not only damages the equipment but may also cause electrical fires. Suitable voltage and current stabilizing devices should be installed, and the equipment should be matched with reasonable loads to avoid long-term overload operation.

Chemical safety hazards and prevention

Electrolyte leakage

Electrolyte is an important component of lithium batteries, which is corrosive and volatile. During the handling and assembly of battery cells, if the container ruptures or seals poorly, the electrolyte may leak. The leaked electrolyte not only corrodes equipment and the working environment, but may also cause harm to the human body. When handling and storing electrolytes, specialized corrosion-resistant containers should be used and the containers should be well sealed. Set up a leak collection device to promptly collect and handle any leaks that occur. At the same time, operators should wear protective equipment such as acid and alkali resistant gloves, goggles, etc.

dust explosion

During the production process of lithium batteries, metal dust such as aluminum powder, copper powder, etc. will be generated. When these dust particles reach a certain concentration in the air, they may explode when exposed to a fire source. To maintain good ventilation in the production workshop and timely discharge dust. Seal the equipment that generates dust and install dust collection devices. Strictly control the sources of fire in the workshop, prohibit smoking and the use of open flames.

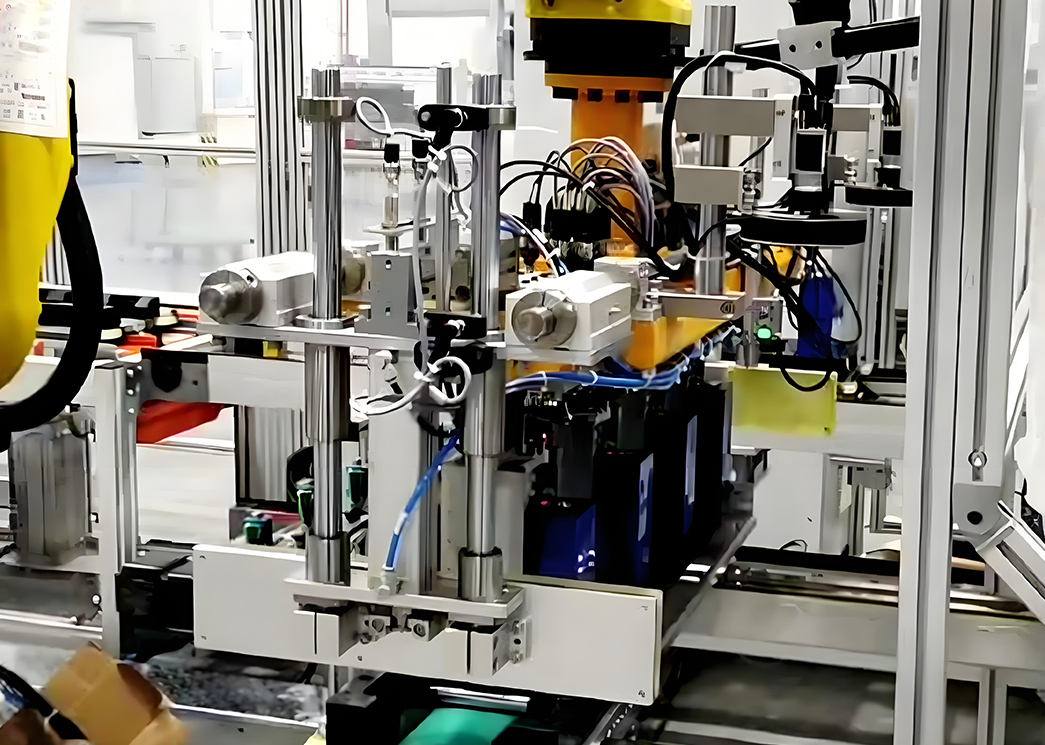

Mechanical safety hazards and prevention

Equipment pinch injury

During the operation of battery cell feeding equipment, module assembly equipment, etc., there are moving parts. If workers operate improperly, their limbs may be injured by the moving parts of the equipment. Install safety devices such as guardrails and shields in hazardous areas of the equipment. Provide strict training to operators to familiarize them with equipment operation procedures and avoid unauthorized operations.

There are various safety hazards in the lithium battery pack production line, covering electrical, chemical, mechanical and other aspects. Only by fully understanding these hidden dangers and taking targeted preventive measures can we ensure the safe operation of the production line, safeguard personnel safety, and ensure the normal production of the enterprise. Enterprises should always prioritize safety, continuously improve their safety management system, and create a favorable safety environment for production.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- Guide for selecting auxiliary gases for laser cutting machines

INQUIRY