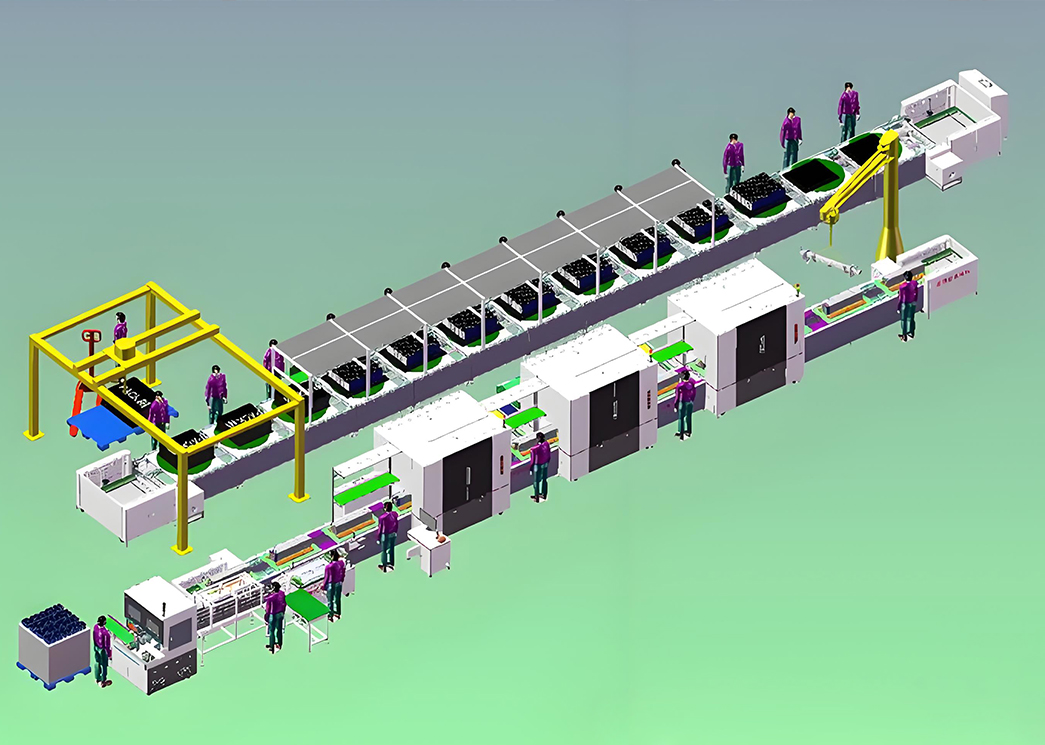

Cell grouping and sorting process in lithium battery module pack production line

In the field of new energy, the application of lithium batteries is becoming increasingly widespread. For lithium battery module pack production lines, cell grouping and sorting processes play a crucial role. They are directly related to the performance of lithium battery modules and fundamentally affect the actual application effect of batteries in various scenarios. Next, Haiwei Laser will provide an in-depth introduction to these two key processes.

Cell assembly

Ensure consistency and improve overall performance

The lithium battery module is composed of multiple battery cells working together. However, the cores are not "identical", and there are slight differences in capacity, internal resistance and voltage. If left untreated and randomly combined, the high-performance battery cells will become overly "exhausted" during charging and discharging, while the weaker ones will have "insufficient output", resulting in a significant reduction in the overall performance of the battery module.

By grouping cells with similar characteristics together, they can work more in sync and achieve consistent charging and discharging states, significantly improving the consistency of battery modules. For example, a properly assembled battery module can significantly improve the uniformity of battery charge during charging and discharging cycles, reducing the risk of overcharging or overdischarging individual cells.

Extend service life and reduce costs

When the battery cells are paired appropriately and the workload is balanced, it is less likely for individual cells to go on strike early due to overuse. Taking the battery pack of electric vehicles as an example, through precise assembly, its service life can be effectively extended. This not only reduces the frequency of battery replacement for users and lowers usage costs, but also enhances product reputation and market competitiveness for battery manufacturers.

Cell sorting process

Capacity sorting

Capacity is a key indicator of a battery cell, reflecting how much electricity it can store. During sorting, professional charging and discharging equipment is used to conduct multiple rounds of charging and discharging tests on the battery cells, accurately measuring their actual capacity. Subsequently, based on the capacity values, the battery cells were classified into different grades. For example, for a battery cell with a nominal capacity of 30Ah, cells with a capacity in the range of 29.5Ah-30.5Ah will be grouped together to ensure that the capacity of cells in the same group is basically the same. This way, when the battery module is working, the power consumption and replenishment rhythm of each cell will be similar.

Internal resistance sorting

Internal resistance reflects the degree of obstruction of current inside the battery cell, directly affecting energy loss and heating during the charging and discharging process. By using a high-precision internal resistance tester, it is possible to quickly and accurately measure the internal resistance of battery cells. Cells with low internal resistance have high charging and discharging efficiency and generate less heat. In the sorting process, cells with similar internal resistance will be selected to ensure that the energy loss of the same group of cells during charging and discharging is similar, maintaining stable performance of the battery module. Usually, the internal resistance difference of the same group of cells should be controlled within a very small range, such as ± 0.3m Ω.

Voltage sorting

The open circuit voltage of a battery cell after being left idle for a period of time can reflect its initial state. Cells with similar voltages exhibit more consistent performance during the initial stages of charging and discharging. During the sorting process, the voltage deviation of the battery cells will be strictly controlled, generally within ± 0.01V, so that each group of battery cells can stand on a similar "starting line", laying the foundation for stable charging and discharging work in the future.

The assembly and sorting process of battery cells is the cornerstone of creating high-performance lithium battery modules. Only by strictly implementing these two processes can lithium batteries play a stable and efficient role in various application scenarios, and promote the new energy industry to reach new heights.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

- Guide for selecting auxiliary gases for laser cutting machines

INQUIRY