What are the design principles for lithium battery pack production lines?

In the current booming development of the new energy industry, the position of lithium batteries is becoming increasingly crucial. As the core facility for manufacturing lithium battery packs, the design of the lithium battery pack production line directly affects product quality, production efficiency, and enterprise benefits. Today, based on practical experience, Haiwei Laser will talk to you about the design principles of lithium battery pack production lines.

Safety comes first

Lithium batteries have special characteristics, and a slight mistake may cause safety issues. So, the design of the production line must prioritize safety. From the beginning of equipment selection, it is necessary to ensure that all electrical components comply with relevant safety standards and have leakage protection and overload protection functions. In the production process, it is necessary to prevent short circuits and overheating of the battery cells during handling, welding, and other operations.

For example, at the welding station, complete smoke exhaust and fire extinguishing devices should be equipped to prevent sparks generated during welding from causing fires. At the same time, multiple safety interlock devices should be installed to automatically stop the operation of the equipment in case of abnormalities, ensuring the safety of operators.

Maximizing production efficiency

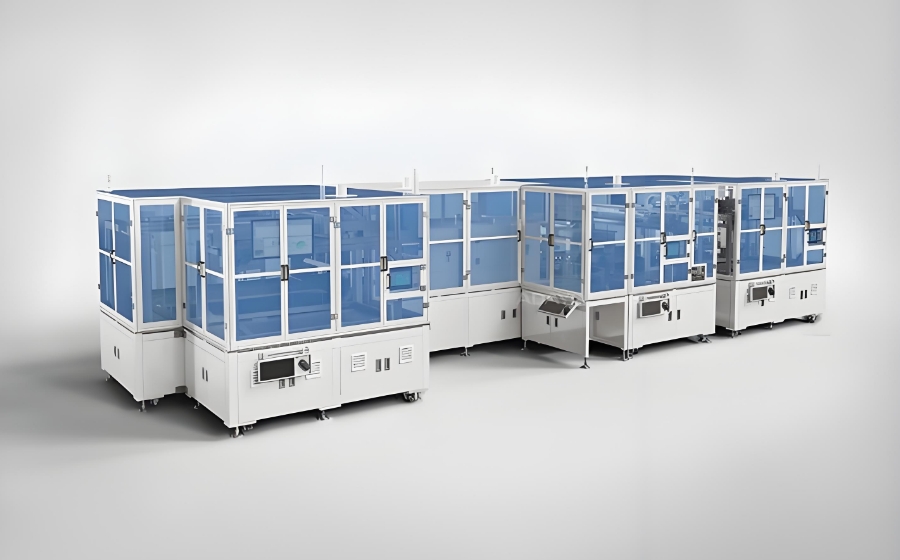

The market has a strong demand for lithium batteries, and improving production efficiency is necessary to meet the supply. The design of the production line should be based on the production process, with reasonable planning and layout to reduce material handling distance and time. Adopting advanced automation equipment, such as high-speed battery cell feeding robots and efficient welding equipment, to achieve seamless connection in the production process.

And, it is necessary to use a scientific production scheduling system to flexibly adjust the production pace according to order requirements, so that the equipment keeps idling and fully utilizes production capacity.

Stable product quality

The quality of lithium batteries is related to product performance and service life. The production line should be equipped with high-precision testing equipment, from the on-site inspection of battery cells, to real-time monitoring during the production process, and then to comprehensive testing of finished products, to achieve full process quality control. For example, after welding the battery cells, high-precision X-ray inspection equipment is used to detect the internal quality of the solder joints and promptly identify issues such as virtual soldering and solder leaks.

At the same time, it is necessary to establish a sound quality traceability system, which can quickly locate the production process and raw material batches in case of quality problems, facilitating improvement and recall.

Flexibility and compatibility

Lithium batteries come in various specifications and models, with different application scenarios. The production line design should have flexibility and compatibility, and be able to quickly switch between producing different specifications of battery cells and modules. By adopting a modular design concept, key components of the equipment can be quickly replaced or adjusted.

For example, the fixtures of welding equipment are designed to be adjustable, which can adapt to the welding of small 3C lithium batteries and meet the production needs of large energy storage system battery packs.

Cost benefit balance

On the premise of ensuring safety, efficiency, and quality, the construction and operation costs of the production line should be considered. Reasonably select equipment and materials to avoid excessive pursuit of high-end configurations and cost waste. At the same time, pay attention to the maintainability of equipment, choose equipment that is easy to maintain and has universal accessories, and reduce maintenance costs in the later stage.

Designing a lithium battery pack production line requires comprehensive consideration of various factors such as safety, efficiency, quality, flexibility, and cost. Only by following these principles can we create a high-quality production line that meets market demand and create greater value for the enterprise. When designing and communicating online, it is important to have a good understanding.

Recent Posts

- What are the advantages of laser welding machines in lithium battery pack production lines?

- What issues should be noted when choosing a lithium battery pack production line?

- Quality Inspection and Control of Lithium Battery Module Pack Production Line

- Cell grouping and sorting process in lithium battery module pack production line

- What are the safety hazards of lithium battery pack production lines and how can they be prevented?

INQUIRY