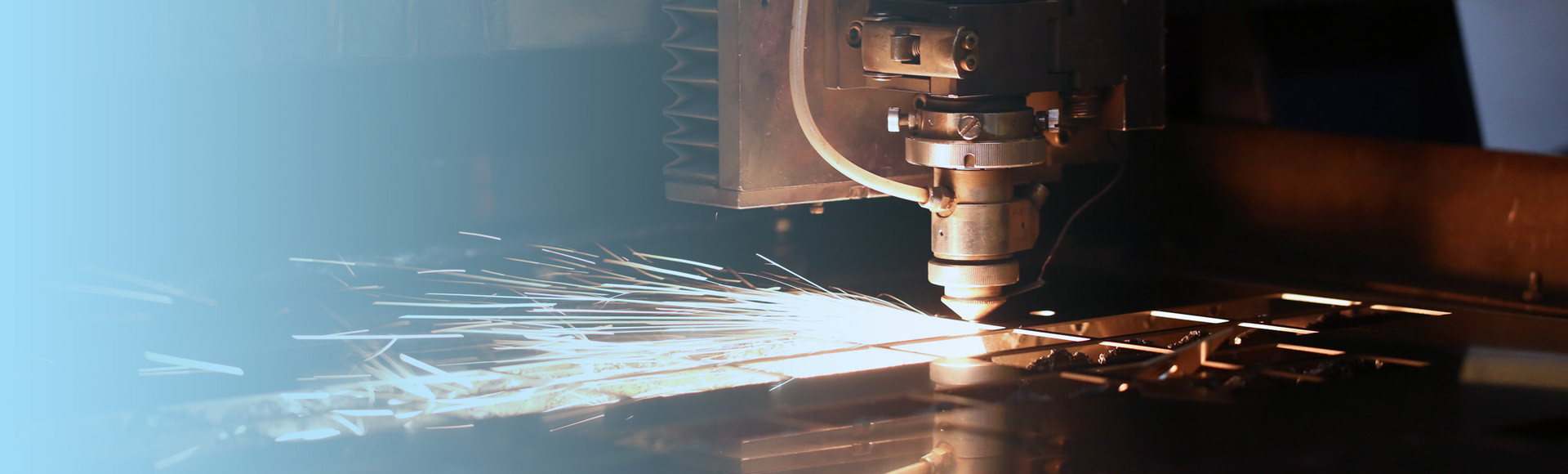

Motor laser welding solution

The manufacturing process of motors is quite complex and diverse, including many links such as stator welding, rotor welding, winding welding, iron core welding, shell sealing welding, shaft and bearing seat welding, etc. Laser welding is considered an extremely suitable process.

Laser welding technology has multiple advantages in the production and manufacturing of motors. Firstly, its high welding accuracy ensures the accuracy and consistency of the welding parts, thereby improving the performance and quality of the motor. Secondly, fast welding speed helps to improve production efficiency and reduce production costs. In addition, the heat affected zone of laser welding is small, which can reduce damage to surrounding materials.

INQUIRY