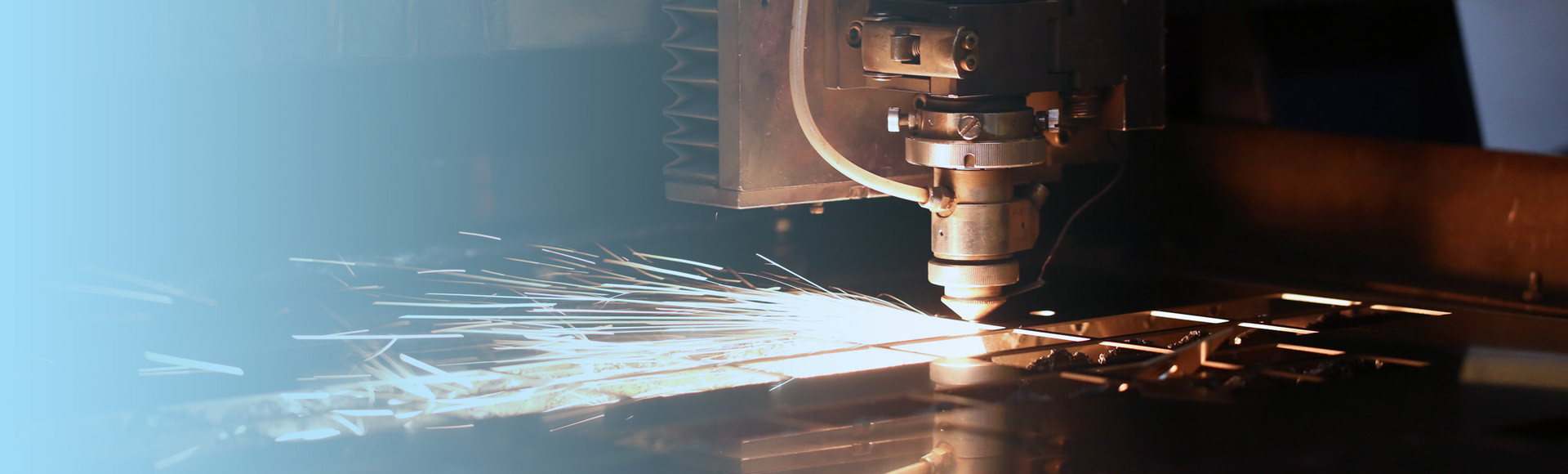

Application scheme of laser welding for mold repair

This plan is specifically developed for the laser welding requirements of mold repair.

Compared to traditional welding methods, it has the following advantages:

Non contact operation: Avoid causing additional damage to the mold.

Low thermal impact: reduces thermal deformation and maintains mold accuracy.

Fast welding speed: improves repair efficiency and shortens production cycle.

In practical applications, we will:

Provide personalized welding solutions for different molds.

Strictly control the welding process to ensure the repair effect.

Provide professional training to operators to ensure standardized operation.

By using this scheme, the following effects can be achieved:

Improve the service life and stability of the mold.

Reduce mold maintenance costs and improve production efficiency.

Ensure the accuracy and quality of the mold to meet high production requirements.

In summary, the laser welding application solution for mold repair provides an efficient and precise solution for mold repair.

INQUIRY