Application Scheme of Nonferrous Metal Copper Aluminum Laser Welding

The structural characteristics of non-ferrous metals copper and aluminum are unique, especially in the welding operation in the joint area, which requires extremely high welding process standards. Traditional welding often leads to uneven weld seams, insufficient bonding strength, a wide range of thermal effects, and subsequently causes problems such as decreased material conductivity and corrosion resistance, which is a major challenge in the industry.

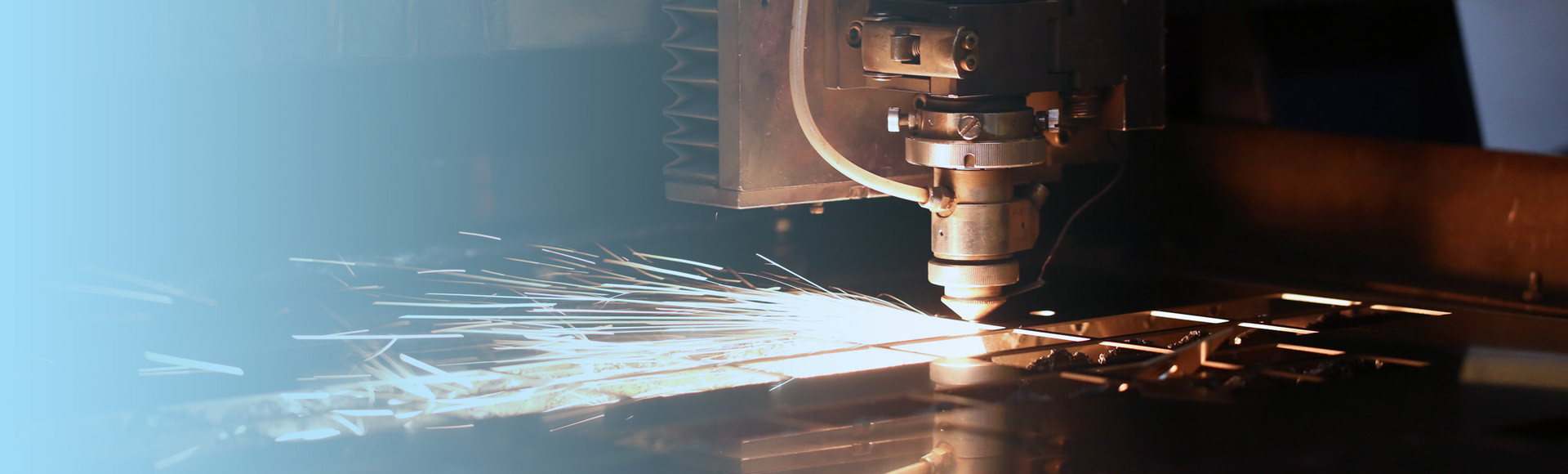

Using laser welding technology to achieve precise and stable welding of non-ferrous metal copper aluminum joints and complex shapes, maintaining the excellent performance of the material and enhancing overall quality.

Laser welding machines fully meet the welding process needs of non-ferrous metals such as copper and aluminum. By introducing this technology, while ensuring product quality, the problem of reduced performance can be effectively resolved, promoting the production of non-ferrous metals such as copper and aluminum to a new height of efficiency, precision, and specialization.

INQUIRY