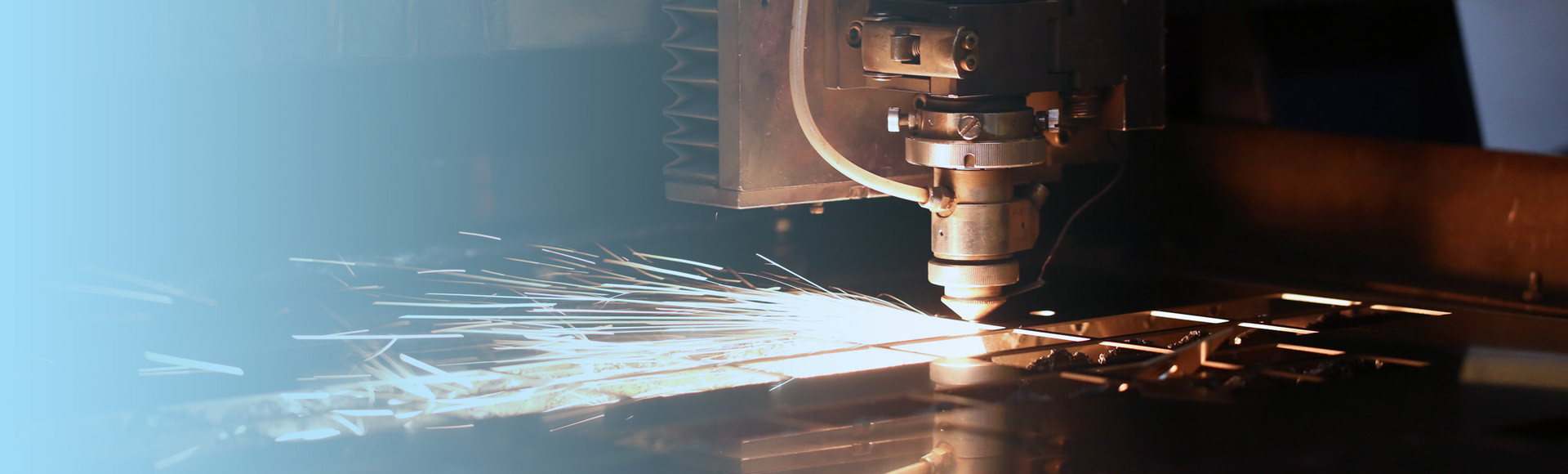

Application scheme of laser welding for sink hardware

The hardware structure of the sink is complex, especially the welding operation at the connection, which requires high welding technology. Traditional welding is prone to rough welds, large heat affected zones, deformation of water tanks, and corrosion, which are long-term challenges faced by the industry.

By using laser welding technology, the connection and complex parts of the sink hardware can be finely and stably welded, avoiding deformation and corrosion, and improving the overall quality of the product.

The metal laser welding machine perfectly meets the needs of the sink hardware welding process. Introducing this technology not only ensures product quality but also effectively solves the above problems, achieving efficient, precise, and specialized production of sink hardware.

INQUIRY