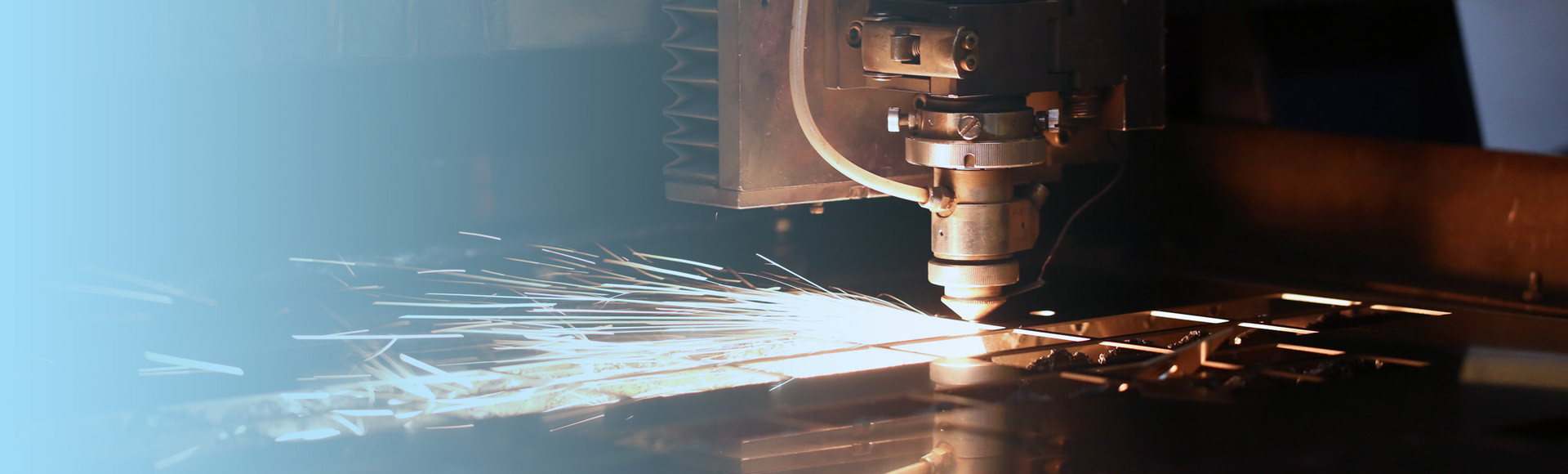

Application scheme of laser welding for faucets

The unique structure of the faucet, especially the welding operation at the turning point, places high demands on the welding process. Traditional welding methods can easily lead to poor weld quality and excessive heat affected areas, resulting in water leakage problems that are a pain point in the industry.

Using laser welding technology to achieve precise and stable welding of the turning parts and other complex structures of the faucet, eliminating water leakage and improving overall product quality.

The metal laser welding machine fully meets the requirements of the faucet welding process. By introducing this technology, it can effectively solve the problem of water leakage while ensuring product quality, achieving high efficiency, precision, and specialization in faucet production.

INQUIRY