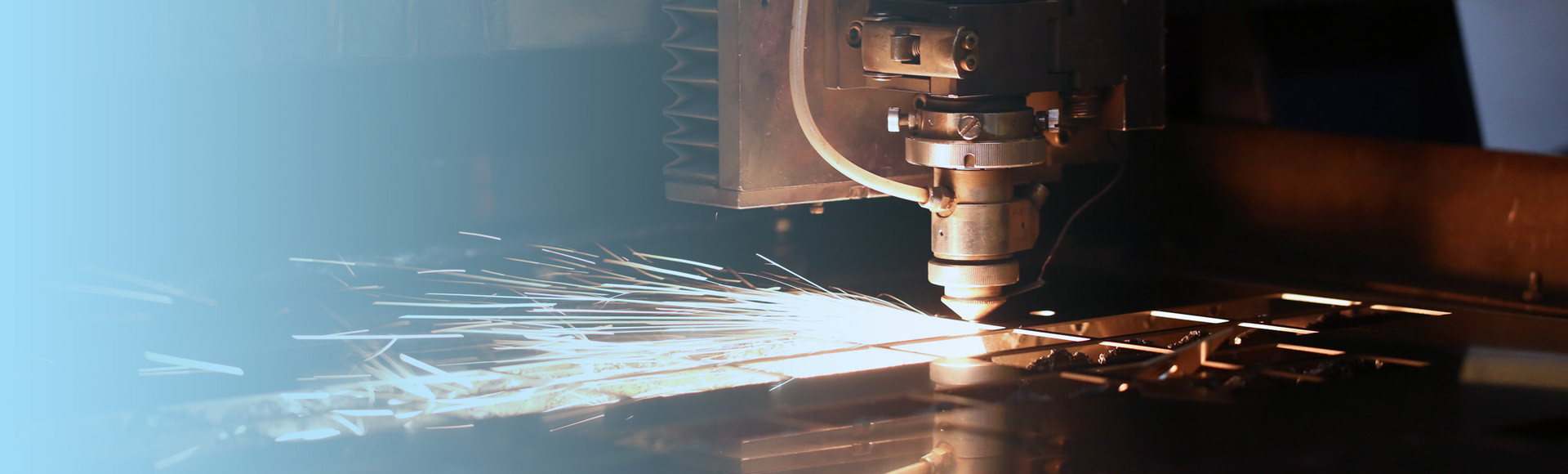

Application scheme of laser welding for advertising lighting fixtures

The traditional welding method often causes problems such as a large heat affected zone, significant deformation, and difficult surface treatment for delicate and delicate lighting workpieces, seriously affecting the aesthetics and durability of the products.

Application scheme of handheld laser welding machine

1、 Precise and efficient welding advantages

Adopting advanced handheld laser welding machines, specially customized for the refined welding needs of the advertising lighting industry. This device can achieve flexible welding operations for long-distance and large-sized workpieces, and its significant features include:

Micro zone thermal impact: The heat input during laser welding is strictly controlled, effectively reducing the heat affected area and avoiding deformation and blackening of the workpiece caused by traditional welding methods, ensuring the integrity and artistic beauty of the lighting fixture are not damaged.

Deep and stable welding: With the ability of deep fusion welding, the welding depth is large and the connection is firm, ensuring the stability and load-bearing strength of the lighting structure, while ensuring tight bonding between various components, preventing virtual welding, desoldering and other situations from occurring.

Perfect weld quality: The unique laser energy distribution technology ensures a smooth transition between the melt pool and the substrate, without obvious depressions or protrusions. The molten material is fully fused, and the weld appearance is clean and beautiful, which can withstand the scrutiny of discerning eyes and harsh use environments.

Handheld laser welding machines provide a revolutionary solution for fine welding in the advertising lighting industry. They not only solve traditional welding problems, but also greatly improve product quality and production efficiency, and will surely lead the advertising lighting manufacturing industry to new heights.

INQUIRY